Likopano tsa Welding tsa Induction bakeng sa Lisebelisoa tsa Voltage e tlase

Kopo

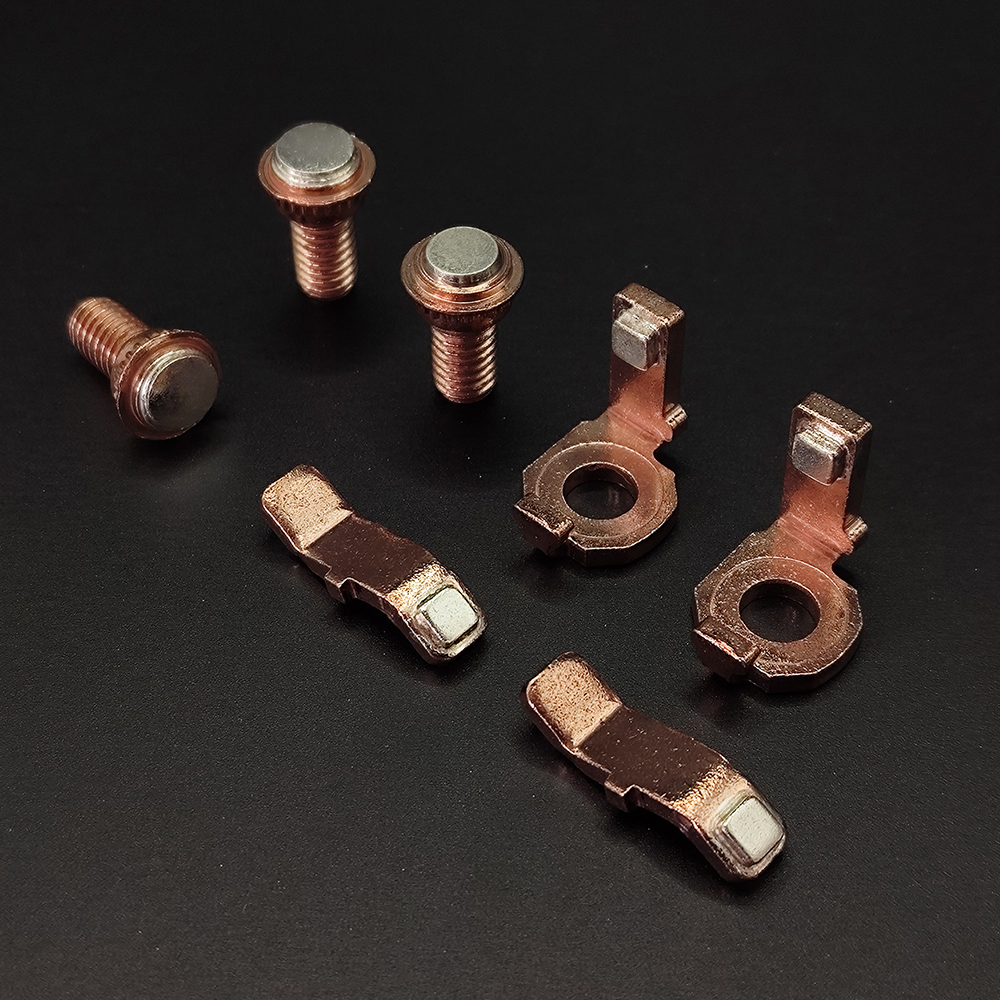

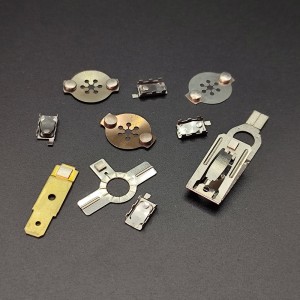

Silver contacts induction brazing e bolela mokhoa oa ho kopanya mabitso a silevera ka mekhoa ea ho kenya letsoho.Ke mokhoa o sebelisoang haholo indastering ea motlakase le ea elektroniki moo likhokahano tsa silevera li sebelisoang hangata bakeng sa conductivity ea tsona e ntle ea motlakase le conductivity e phahameng ea mocheso.

Indction brazing e kenyelletsa ho sebelisa coil ea induction le jenereithara ea maqhubu a mahareng kapa a phahameng ho hlahisa mocheso ka induction ea motlakase.Joale mocheso o sebelisoa ho likarolo tsa silevera tsa ho kopana, ho etsa hore li fihlele mocheso o lakatsehang oa brazing.Molemo oa ho kenya letsoho ke hore o fana ka mocheso o potlakileng le oa sebakeng sa heno, o fokotsa ho fetisetsa mocheso libakeng tse ling le ho fokotsa kotsi ea ho sotha kapa ho senya thepa e potolohileng.

Ha o kopanya mabitso a silevera, ke habohlokoa ho khetha lisebelisoa tse loketseng tsa ho roala tse lumellanang le silevera, tse kang li-alloys tse entsoeng ka silevera.Alloy brazing e sebelisoa e le lisebelisoa tsa ho tlatsa motsoako, ho etsa maqhama a matla le a ka tšeptjoang pakeng tsa likarolo tsa ho kopana le silevera.

Ts'ebetso ea induction brazing e ka ntlafatsoa bakeng sa likopano tsa silevera tsa boholo le libopeho tse fapaneng, 'me e fana ka melemo e kang taolo e nepahetseng ea mocheso, ho futhumatsa ka lebelo le phahameng le liphetho tse tsitsitseng.Ke mokhoa o tsebahalang oa ho kopanya mabitso a silevera ka lebaka la ts'ebetso ea ona le bokhoni ba ho hlahisa likhokahano tsa boleng bo holimo, tse tšepahalang.

Silver contacts induction brazing ke mokhoa o sebetsang hantle, o nepahetseng le o ikemetseng o nang le litšobotsi tse latelang:

● Katleho: Silver point induction welding e sebelisa mocheso oa ho futhumatsa, o ka futhumatsang sebaka sa welding kapele ka nako e khuts'oane le ho fihlela welding ka lebelo le phahameng.Ha ho bapisoa le mekhoa ea khale ea li-welding, katleho ea tlhahiso e ka ntlafatsoa haholo.

● Ho nepahala: Silver point induction welding e thusa ho laola mocheso oa welding le nako, e leng se lumellang hore ho be le taolo e nepahetseng ea boleng ba welding nakong ea ts'ebetso ea welding.Litsamaiso tsa ho shebella le ho laola mocheso nakong ea ts'ebetso ea welding li ka netefatsa ho tsitsisa le botsitso ba liphetho tsa welding.

● Automation: Silver point induction welding hangata e sebelisa lisebelisoa tse ikemetseng ho iketsetsa ts'ebetso ea welding.Sena ha se ntlafatse katleho ea tlhahiso feela, empa hape se fokotsa matla a mosebetsi oa basebetsi.

● Taolo ea mocheso: Silver point induction welding e sebelisa mocheso oa ho futhumatsa ka potlako ho futhumatsa sebaka sa welding ho mocheso o hlokahalang, ho qoba bothata ba ho chesa kapa ho chesa ka tlaase.Ka nako e ts'oanang, mocheso oa welding o ka fetoloa ka nepo ka lisebelisoa tsa taolo.

● Boleng ba tjheseletsa: Silver-point induction welding e sebelisa solder e nang le lintlha tse phahameng tsa silevera.Lenonyeletso le cheselitsoeng le na le matla a holimo, boleng bo botle ba weld, ho hanyetsa kutu e matla, 'me e ka kopana le lits'ebetso tsa ho tjheseletsa tse batloang haholo.Ho akaretsa, welding ea ntlha ea silevera e na le litšobotsi tsa ts'ebetso e phahameng, ho nepahala, ho iketsetsa le boleng bo holimo.E loketse bakeng sa ho cheselletsa lisebelisoa tse sa tšoaneng tsa tšepe 'me ke mokhoa oa bohlokoa oa theknoloji ea morao-rao ea ho tjheseletsa.